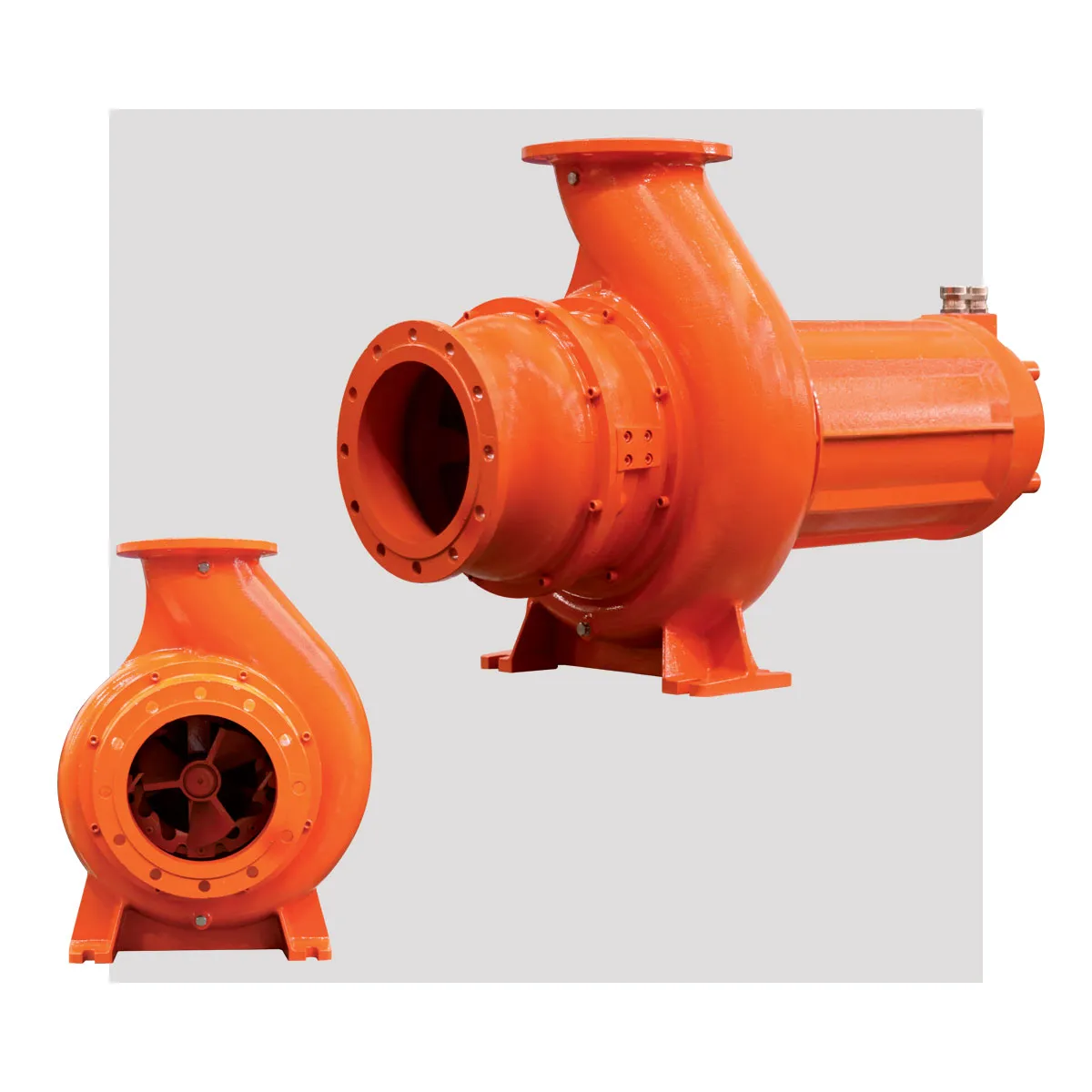

Pumps

for Biogas plants

CRI-MAN offers the broadest range of chopper pumps

for Biogas plants

They are used for feeding the primary digester, to transfer the substrate between digesters and for mixing inside the digester by means of nozzles. The chopping system.

provided in all CRI-MAN pumps facilitates the anaerobic fermentation process, thereby improving plant efficiency.

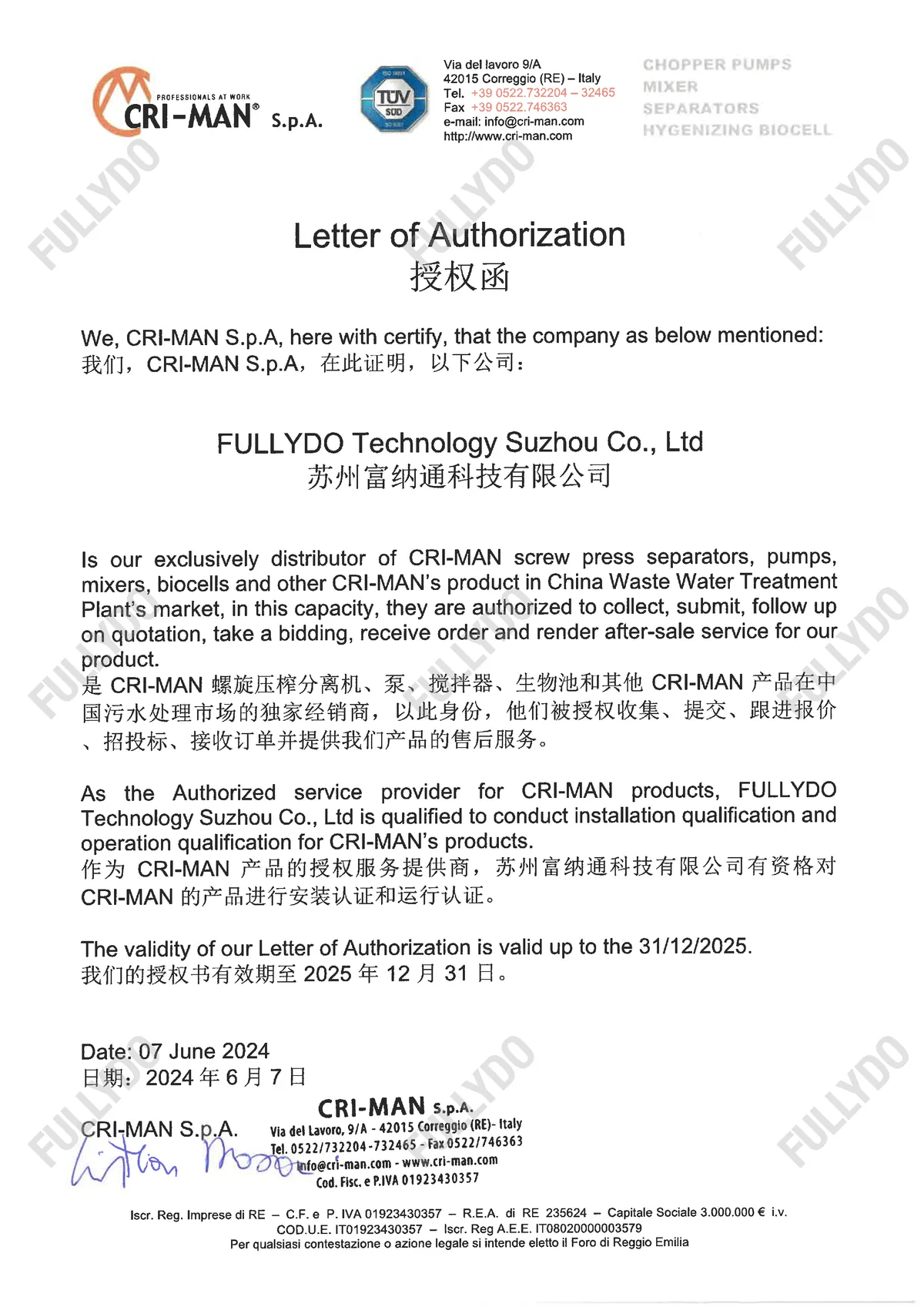

Authorized Exclusive Distributor in China

Fullydo Technology Suzhou Co., Ltd is the officially certified exclusive distributor for CRI-MAN in China's waste water treatment market.

Exclusive Distribution Rights

We are authorized to collect, submit, and follow up on quotations, take bids, receive orders and render after-sale service for CRI-MAN products in China.

Our Qualifications

- Installation qualification and operation qualification for CRI-MAN products

- Comprehensive after-sales service and maintenance

- Participate in bidding processes and quotations

Trusted Partnership

Official authorization from CRI-MAN S.p.A, certified and verified partnership for the Chinese market.

Chopper pumps

our complete range for Biogas plants

PTS 65 SERIES

Flow rate: 110 m³/h

Head: 29 m

Power rating: 7.5 - 11 kW

PTS 80 SERIES

Flow rate: 140 m³/h

Head: 46 m

Power rating: 2.2 - 18.5 kW

PTS 100-150 SERIES

Flow rate: 460 m³/h

Head: 21 m

Power rating: 4 - 22 kW

PTS 200 SERIES

Flow rate: 720 m³/h

Head: 18 m

Power rating: 15 - 30 kW

PTE / PTEM SERIES

Flow rate: 460 m³/h

Head: 21 m

Power rating: 4 - 22 kW

ETO SERIES

Flow rate: 460 m³/h

Head: 112 m

Power rating: 0.75 - 75 kW

ETV SERIES

Flow rate: 460 m³/h

Head: 51 m

Power rating: 2.2 - 22 kW

ETO 200 / EPO 200 SERIES

Flow rate: 720 m³/h

Head: 22 m

Power rating: 22 - 45 kW

CFS SERIES

Power rating: 11 - 22 kW

Max flow rate: 50 m³/h

PLD SERIES

Flow rate: 50 m³/h

Head: 80 m

Hydraulic engine power rating: 9.2 kW

Strengths

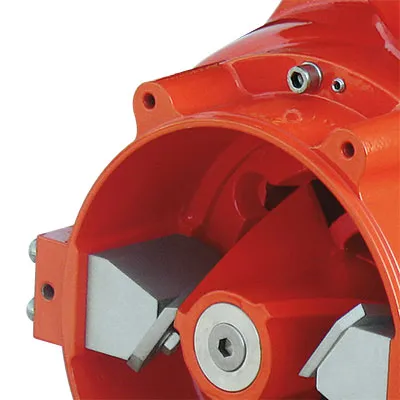

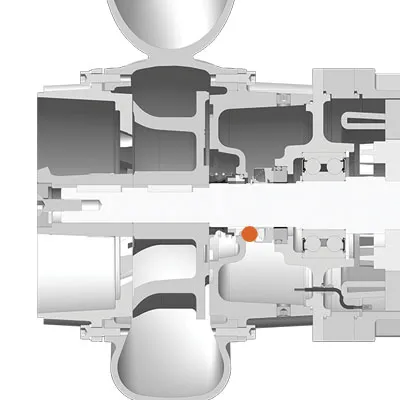

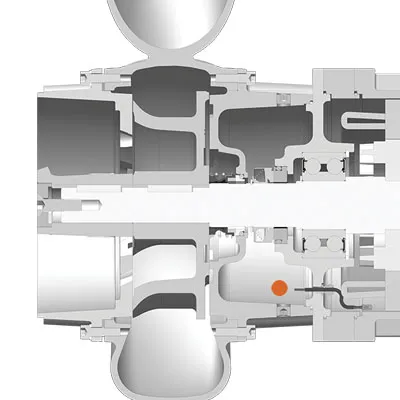

Double chopping system

The first chopping system is formed by two chrome steel blades fixed to the suction part that skim over a conveyor plate in special cast iron fixed to the rotating shaft. Both materials are subjected to a specific hardening treatment. In a 1450 rpm pump, the first chopping system alone operates at a rate of 140 cuts/second!

Double chopping system

The second chopping system features a toothed plate in special cast iron which skims over an impeller, also in special cast iron, with sharp-edged blades. Both materials are subjected to a specific hardening treatment.

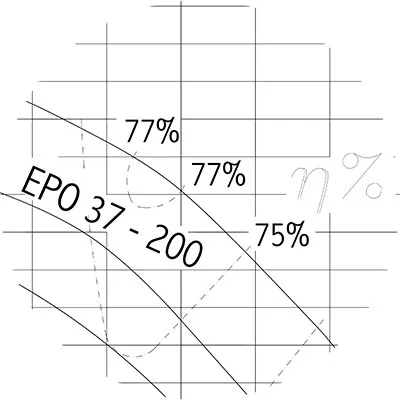

High efficiency hydraulics

Hydraulics designed to combine high efficiency (up to 77% efficiency rating) and strong chopping power without clogging. Data in accordance with UNI EN ISO 9906 standards.

Double mechanical seal *

Mechanical seals in Silicon Carbide and Carbon-Ceramic

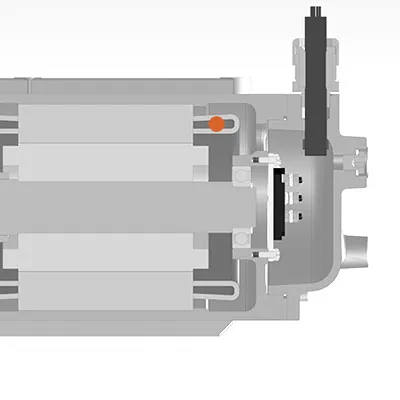

Temperature sensors

Double temperature sensors embedded in the stator to prevent the motor from overheating and ensure it continues to function correctly over time.

Humidity sensor (if requested) *

The humidity sensor is installed in the oil chamber to prevent damage should fluid leak out.

* Double mechanical seal and Humidity sensor not available for all pump versions.

Accessories

Broad range of accessories for every type of pump installation.